Hollow Core units have longitudinal cores of which the main purpose is to reduce the cost and importantly the weight of the element. They are available in different depths, in order to satisfy the various performances needs for span and loading. These units are normally 1200mm wide, although other dimensions are also available. The actual unit width may be 3 to 6mm less than the nominal size to allow for construction tolerance. Hollow core slabs are used in places where large spans are required like schools or auditoriums and also in social housing projects due to the enormous cost savings. It is suitable for Fast Track Projects.

Pre-stressed Precast Hollow Core units are manufactured using various methods of which slip forming process and long line intrusion are the most competitive ones. The degree of pre-stress, strand pattern and depth of unit are the major design parameters. After the units have hardened the elements are normally cut to the specified lengths. Though a rectangular end is standard, skew or cranked ends, which may be necessary for non rectangular floor plan, can also be cut out. The edges of the units are profiled to ensure adequate vertical shear transfer across the grouted joint between adjacent units. The shear capacity in the grouted joints will be sufficient to provide transverse distribution of loads without the use of in situ structural topping

Nael Cement Products following a curing system as per Quality System Procedure ACI 318, PCI MNL-116/117, & structural calculations. Soon after the finishing of casting, the exposed surfaces will be fully covered with plastic polyethylene sheets to prevent free water moisture over the slab. In addition to the above curing method Hollow Core Slabs will be cured with fresh water after attaining the initial strength of concrete up to transfer of pre stress, if required.

»» Precast Slabs can be classified, according to their manufacture, as totally and partially Precast Slabs. Totally Precast Slabs are composed of units which are totally cast at the plant. After erection, the units are connected to the structure and the constitutional joints are grouted. In some cases, a cast in situ structural topping is added to increase the load bearing capacity ( in the case of floors). Partially Precast Slabs are composed of both Pre cast as well as Cast in situ parts. Both parts work together, when completed, to achieve the needed structural capacity. Here we will be dealing exclusively with totally Precast Hollow Core Slabs.

»» Slab depths in production range from 150 mm to 500 mm and widths are usually 1200 mm wide but other smaller widths are also available.

»» Hollow Core Slabs are designed to have effective shear key joints between adjacent slabs such that when grouted the individual slabs become a system that behaves similar to a monolithic slab.

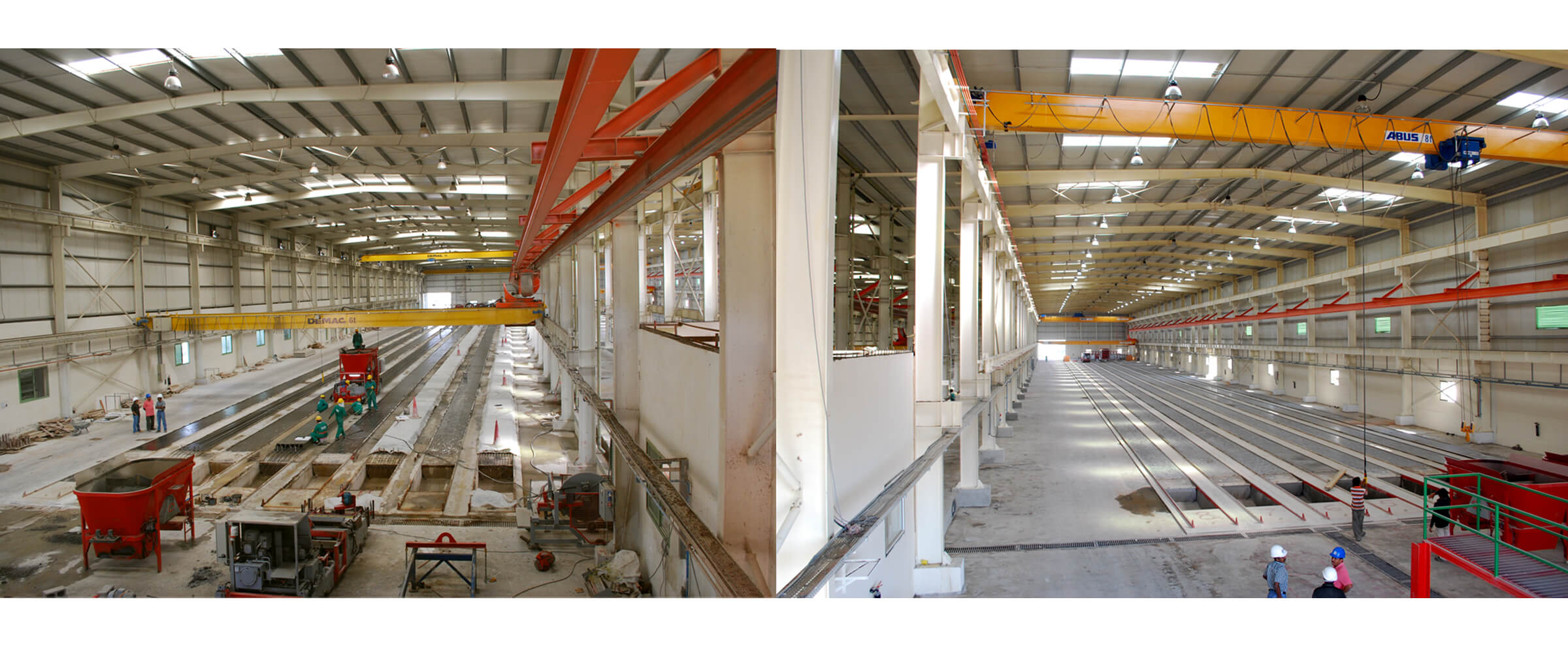

»» Production capacity: 2500 to 2800 sq/m per day.

»» Erection capacity : 500 to 800 sq/m per day.

»» The fire resistance of a Hollow Core Slab element depends upon cover to reinforcement and the thickness of the slab. Hollow core slabs are available with fire resistance for periods between 1 and 3 hours without the application of further materials, based on client requirements.

»» Hollow Core Slabs may be used in conjunction with a structural topping where enhanced performance is required e.g. heavy point loads, complex structural integration, heavy service penetration etc.

»» Since the soffit of a Hollow Core Slab is generally formed from a steel mould, it is suitable for exposed finish in structures such as car parks and industrial buildings, and for a wide variety of applied finishes in other types of building. Top finish to the precast slab is designed to receive a levelling screed / structural topping or an appropriate flooring system.

»» Precast Hollow Core Slabs are suitable to satisfy the requirements of the Building Regulations for sound insulation. Precast Concrete Hollow Core Slabs are also recommended for use at first floor level in villas to create a quiet home for the benefit of the client.

»» Prestressed Hollow Core Slabs will exhibit an upward camber, the degree of which will depend upon the span and the amount of prestressing force applied. Due allowance must be made for this, in determining finishes and overall floor thicknesses.